Maple Syrup Concentration

Download Full Case StudyBackground

In the production of maple syrup, maple sap is concentrated from roughly 2% sugar to 66%+ sugar. This concentration is achieved primarily by evaporation, which is a very costly and energy intensive process. If the sap can be processed and concentrated with membrane technology to reduce the evaporation required to achieve a 66%+ sugar concentration, a significant cost savings could be seen by maple syrup producers. Synder’s NFX Nanofiltration membrane was tested against the leading competitor’s NF membrane to gauge performance in concentrating the sap from 2-8% sugar.

Feed Solution, Membrane, and Operating Conditions

(Table 1)

| Feed Solution | |

| Material | Diluted Maple Syrup (2% Sugar Concentration) |

| Dilution Factor | 34 |

| Synder Membrane | |

| Element | NFX-2-2540HM |

| Spacer Size (mil) | 31 |

| Surface Area (sq. ft) | 27 |

| Competitor’s Membrane | |

| Spacer Size (mil) | 31 |

| Surface Area (sq. ft) | 27 |

| Operating Parameters | |

| Inlet Pressure (PSI) | 110 |

| Temperature(°C) | 17-33 |

| Crossflow Rate (GPM) | 4.5-5 |

| Run Time (min) | 50-55 |

| Feed VOlume (Gal) | 20 |

Results

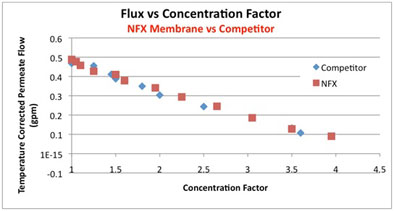

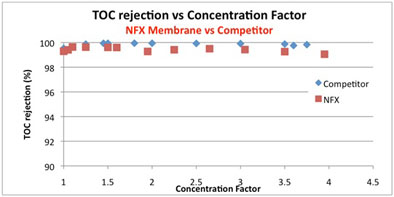

Both NF membranes required 50-55 minutes to achieve an 8% sugar concentration. Given the linear correlation between TOC and total brix, TOC and conductivity measurements were used to evaluate the salt rejection and sugar retention of the membranes. The performance of the NFX membrane in respect to permeate flux and sugar rejection is described in the graphs below.

Conclusion

Synder’s NFX membrane displayed similar performance to the leading competitor and proved effective in concentrating maple syrup from 2% to 8%. The two membranes showed similar permeate flux while the sugar concentration in the NFX permeate was below 0.1 brix over the entire concentration process. This study suggests that Synder’s NFX membrane offers very competitive performance for the concentration of maple sap and could lead to significant cost reductions in the production of maple syrup.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS